Energy management system ISO 50.001

Natural gas and electricity are required for the production of wallpaper. Natural gas is needed to operate a so-called ‘thermal exhaust air purification’ system and for heating. We need electricity to operate our production facilities and to generate compressed air and cooling.

As part of our ISO 50.001 certification, we have developed a holistic energy concept to ensure efficient energy use. Heat exchangers are used in the thermal exhaust air purification systems so that the process heat generated can be used, for example, to dry the inks in the printing process. This saves energy and reduces the remaining waste heat potential to a minimum.

Energy transition in companies – use of renewable energies

A.S. Création Tapeten AG in Germany has been purchasing green electricity since 2021. This change results in annual savings of 2,000 to 3,000 tonnes of CO2 equivalents. This is equivalent to the heating of around 1,000 single-family homes.

The renewable energy was sourced from various hydroelectric power plants across the EU. A.S. Création will continue to rely entirely on green electricity in 2025, with a specific focus on certified green electricity from Germany.

Whereas in the past, green electricity was mainly sourced from hydroelectric power in Northern Europe, the focus is now on promoting renewable energies such as wind, hydro and solar energy within Germany. In this way, A.S. Création is helping to achieve national climate targets and making an important contribution to the transformation of the energy sector.

The green electricity used is certified by guarantees of origin, which ensures that every kilowatt hour consumed is clearly attributed to A.S. Création and that double counting is avoided. With this decision, the company is taking another important step in its ‘GREEN STEPS’ sustainability strategy.

Climate protection at the heart of A.S. Création's sustainability efforts

Climate change is one of the greatest challenges of our time. A.S. Création Tapeten AG is aware of its contribution to climate change as a manufacturing company and therefore places climate protection at the heart of its sustainability efforts. We are pushing ahead with extensive measures to reduce our greenhouse gas emissions in order to help ensure that the Paris Climate Agreement is still met despite the poor prognosis and to limit global warming to well below 2 degrees Celsius.

The carbon footprint of A.S. Création Tapeten AG

The basis for our climate protection measures is the annual calculation of the company's carbon footprint. By 2024, we will have calculated five carbon footprints. The comprehensive understanding of our impact on climate change gained from these calculations enables us to identify targeted climate protection measures and continuously measure their effectiveness. Our absolute CO₂ emissions have developed as follows over the past five years.

| Emissions in tonnes of CO2 | 2020 | 2021 | 2022 | 2023 | 2024 |

| Scope 1 (heating, cooling, vehicle fleet) | 8.939 | 8.640 | 6.974 | 6.043 | 6.023 |

| Scope 2 (electricity) | 3.246 | 0 | 0,00 | 0,00 | 0,00 |

| Scope 3 (purchased goods, logistics, disposal, etc.) | 101.568 | 83.026 | 59.312 | 50.025 | 49.127 |

| Total emissions | 113.753 | 91.666 | 66.286 | 56.068 | 55.150 |

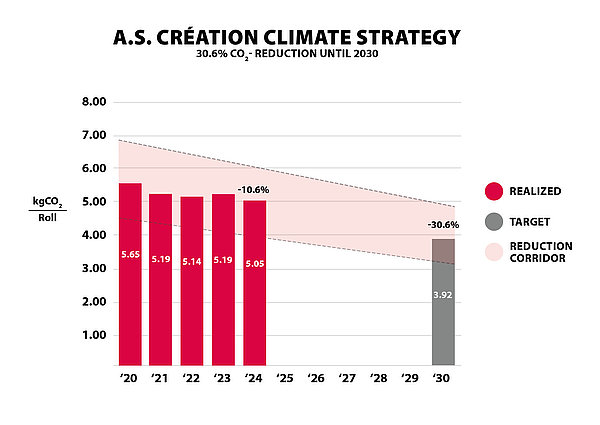

The 30.6% target – our CO2 reduction concept:

A.S. Création is aware that determining emissions alone is not enough to contribute to compliance with the Paris Climate Agreement. Rather, this requires deriving a reduction strategy from the carbon footprint, defining concrete reduction measures and implementing them consistently. A.S. Création has therefore identified potential areas for CO2 reduction.

When determining the reduction potential, each individual emission category in the carbon footprint was examined separately. This examination was based on internal analyses, supplier surveys and the evaluation of scientific sources. A 10-year period, from the starting year 2020 to the target year 2030, was set as the target horizon.

A.S. Création Tapeten AG has set itself the following goal for its production site in Germany:

We want to reduce total greenhouse gas emissions in categories Scope 1 to Scope 3:

from 5.65 kg CO2e per euro roll of wallpaper in 2020

to 3.92 kg CO2e per euro roll of wallpaper in 2030.

This corresponds to a reduction of 1.73 kg CO2e per roll of wallpaper, or -30.6%.

The graph above shows that we are on the right track with our reduction concept. Emissions per euro roll of wallpaper produced are falling steadily within the defined corridor, for example through the switch to 100% CO2-neutral electricity and identified efficiency potentials.

In order to achieve our goal by 2030, strategic projects have been launched in areas with a long timeframe, which are being implemented by specialised teams.

• Material substitution and improvement

• Modernisation of production facilities, processes and energy technology

• Sustainable optimisation of packaging

• Circular economy

The gradual implementation of measures within these processes will help us achieve our reduction target by 2030.

Everything for the bin, or not? What happens to the wallpaper after the renovation?

Wallpaper usually consists of a layer of paper or non-woven fabric, which serves as a carrier material for the printing inks applied in a further step to create the decorative pattern of the wallpaper. Another popular product feature is a textured ‘3D surface’. This is created by applying an embossed plastic layer. However, the pattern structure described above means that different materials are firmly bonded together.

There are technical methods for separating the plastic layer from the paper layer, thereby obtaining two reusable material fractions. These techniques are used, for example, in the recycling of internally generated production rejects. However, the disposal channels available to end consumers are not designed for the separation of these materials, meaning that wallpaper must be disposed of as residual waste after use. For this reason, A.S. Création focuses on minimising the environmental impact of the product on the input side.

Further development of the product into a recyclable material is currently being evaluated. However, beyond the purely technical and material-related challenges, there is also the problem that, after a long period of use, the customer must still perceive the product as a recyclable material when removing it and dispose of it in the correct waste stream. In addition, the removal of wallpaper often generates additional construction waste. As this mixes with the wallpaper waste, recyclability is significantly impaired. The vision of a ‘recyclable wallpaper’ is therefore a major challenge that may not be achievable.

The packaging, on the other hand, is 100% recyclable. The product is delivered together with a paper insert containing all the important product information. To protect the product from dirt and damage during transport and in the shop, it is packaged in transparent PE shrink wrap. The transport packaging for the delivery of an entire packaging unit is a cardboard box made of corrugated cardboard. All packaging components are 100% recyclable.

We are also working to ensure that the packaging materials themselves contain a high proportion of recycled material. In the case of our film, for example, this is 30% post-consumer recycled material.

Recovering recyclable materials and promoting the circular economy

‘You can't make an omelette without breaking eggs.’ These proverbial ‘eggs’ are nothing more than industrial waste, and of course this also occurs in wallpaper production.

In wallpaper production, the largest proportion of operational waste is generated by rejects. These rejects are unavoidable for technical reasons due to the nature of the printing process. This is primarily due to colour settings. In addition, further waste is generated unexpectedly due to production errors. Together, these two fractions form what is known as ‘pure wallpaper waste’.

In addition, the production of wallpaper generates waste in the form of solid and liquid residues, which arise, for example, during the cleaning of printing tools. Finally, packaging materials and typical production waste, such as scrap metal, wood waste and municipal waste from the administrative area, also contribute to the total waste volume. Hazardous waste plays a minor role in A.S. Création's business operations. This includes absorbent and filter materials contaminated with oils, as well as some construction and demolition waste.

The total waste volumes in the A.S. Création Group in 2024 are as follows. You can find more detailed information on the circular economy key figures in the CSRD Report 2024.

Recycling and reuse instead of incineration

In order to avoid wasting raw materials, we have entered into cooperation with waste disposal companies to find material recycling methods (no incineration or chemical dissolution) for the ‘pure wallpaper waste’ fraction. One result of this cooperation, for example, is the manufacture of sound insulation products from this waste fraction. Another material stream flows into the paper industry as an auxiliary material after processing.

In 2024, A.S. Création Tapeten AG succeeded in recycling 98.5% of its pure wallpaper waste. Approaching a value of 100% is an important annual target for A.S. Création in the area of circular economy.

At A.S. Création Tapeten AG, we also monitor the so-called ‘separate collection rate’. Separately collected waste is sent for material-appropriate recycling and can thus be recycled. In contrast, mixed waste is usually sent for incineration. This rate was 98% in 2024.

Sustainable procurement – use of secondary raw materials in production

In its ‘Sustainable Procurement Policy’, A.S. Création sets out procedures for increasingly switching to recycled materials in its procurement of raw materials and reducing the use of primary raw materials.

In order to do this in a data-based and objective manner, we obtain product carbon footprints (PCFs) from suppliers in order to evaluate the sustainability performance of individual raw materials and compare them with the initial product. This enables us to identify more climate-friendly raw material alternatives.

There is a particular focus on replacing fossil-based raw materials with bio-based or recycled alternatives. The purchasing strategy also includes increased cooperation with suppliers who offer alternative recycled materials, thereby ensuring continuous improvement in material efficiency and circular economy.

Other important objectives within the framework of our sustainable procurement policy are the reduction of harmful substances in key raw materials and the promotion of renewable energies in the supply chain. Suppliers who are particularly advanced in terms of the aforementioned sustainability aspects receive a better rating in the company's own supplier assessment.

Through these measures, A.S. Création Tapeten AG is laying a solid foundation for the gradual shift away from primary raw materials and for sustainable and resource-efficient procurement practices that contribute to reducing environmental impact and meeting climate targets.

Sustainable forestry – certified and deforestation-free paper

A.S. Création has an impact on the forest ecosystem through its purchase of paper products. Healthy forests play a central role in safeguarding intact ecosystems worldwide, promoting biodiversity and protecting the climate, water and soil. That is why our goal must be to value the forest habitat, which is threatened by humans, and to preserve it in good condition. This principle is also enshrined in our environmental policy.

In order to contribute to the preservation and restoration of the forest ecosystem, another core principle of sustainable procurement is to source wood products exclusively from responsibly managed, (FSC) certified forests.

Within the framework of the EU Deforestation Regulation (EUDR), we analyse our purchases of wood products (and other EUDR-relevant products, where applicable) for potential deforestation risks. This represents another important safeguard for the procurement of ecologically and socially responsible raw materials.